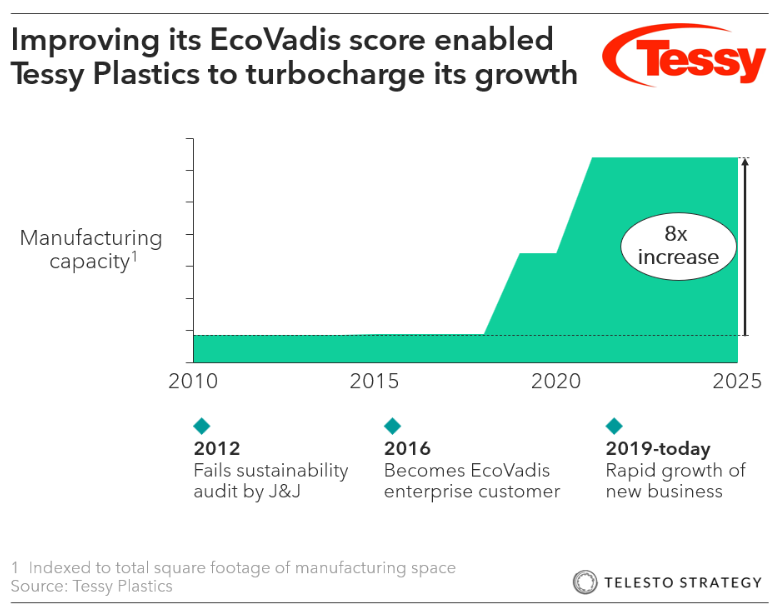

For small and mid-sized manufacturers, sustainability assessments like EcoVadis can initially seem like compliance hurdles. However, for Tessy Plastics, a U.S.-based injection molding company, embracing EcoVadis became a catalyst for significant business transformation and revenue growth.

Need

In 2012, Tessy Plastics faced a pivotal challenge. A failed sustainability audit by its primary customer, Johnson & Johnson (J&J), coupled with a low initial EcoVadis score, put their long-standing relationship at risk. Recognizing the need for immediate action, Tessy embarked on a comprehensive sustainability overhaul.

Response

To address the shortcomings and rebuild trust, Tessy Plastics undertook several key initiatives:

- Applying EcoVadis Tools: Used EcoVadis assessments, scores, and corrective action plans, together with EcoVadis and ESG expertise, to better understand and quantify their initial position and as a roadmap for continuous improvement.

- Stewardship Program Launch: Introduced to foster internal buy-in and momentum for sustainability efforts.

- Focused Improvements: Initially targeted strengths like health and safety, further expanded to broader ESG areas.

- Certifications and Reporting: Obtained essential management system certifications, set CSR targets, implemented a waste reduction scheme, and began reporting to more disclosure databases.

Within five years, Tessy Plastics transformed its operations and market position:

- Operational Expansion: Grew from a 300,000 sq. ft. facility in New York to more than 3 million sq. ft. of operations across New York, Virginia, and Shanghai.

- Enhanced Customer Relationship: Evolved from J&J’s lowest-performing supplier to a leading manufacturer for plastic parts, excelling in revenue, diversity, sustainability, and environmental health and safety leadership.

- Industry Recognition: Received J&J’s Supplier Sustainability Award in 2015 and was featured in their 2017 Health for Humanity Report.

- Global Advocacy: Cindy Bush, Director of EHS at Tessy, spoke at the United Nations in 2017, highlighting the role of SMEs in advancing Sustainable Development Goals through sustainability transformations.

Extending Impact Through the Supply Chain

In 2016, Tessy Plastics became an EcoVadis Enterprise customer, extending sustainability assessments to its own suppliers. In addition to improving their own EcoVadis score and thus further delighting its customers, becoming an Enterprise customer also allowed Tessy Plastics to exert more influence and control over their own suppliers to drive quality and transparency. This further created a virtuous cycle, as the improving EcoVadis scores of Tessy’s suppliers also improved Tessy’s own EcoVadis score, further distinguishing Tessy to its target customers.

Key takeaways for manufacturers

- Proactive engagement leads to long-term wins. Tessy Plastics’ experience shows that early, proactive steps toward sustainability can do more than meet customer expectations, they can reshape a business. After a failed audit, Tessy leaned into the EcoVadis platform and turned a potential setback into a five-year growth story. For manufacturers new to ESG, taking action early isn’t just smart risk management—it’s a chance to lead and differentiate.

- Strategic use of EcoVadis drives measurable results. Tessy didn’t simply “check the box” with EcoVadis—they used it as a framework to guide operational improvement. The result? A Gold rating, expanded operations, and stronger customer trust. Their experience shows that EcoVadis isn’t just about scoring, it can be a catalyst for long-term growth.

- Cross-functional ESG execution is crucial. Tessy Plastics succeeded by bringing cross-functional leaders to the table — from safety and quality to HR and executive leadership. Because ESG performance spans the entire organization, companies that isolate the work in one department often struggle to gain traction or drive lasting impact.

- Supplier-led transparency builds competitive moats. After strengthening their own ESG practices, Tessy took it further, using EcoVadis to assess and engage their suppliers. This move positioned them to be not only compliant, but a sustainability leader in their value chain. In today’s market, leading on supply chain responsibility builds trust, deepens loyalty, and sets companies apart.

- Real business growth comes from ESG excellence. One of the most powerful outcomes of Tessy’s journey was its direct impact on revenue growth. Their turnaround story led to deeper customer partnerships, industry award recognition, and facility expansion. It’s a clear example that sustainability isn’t just good practice—it’s a driver of business growth.

Tessy Plastics’ story is inspirational—but not every company has the internal bandwidth or expertise to manage such a transformation solo. That’s where a partner like Telesto Strategy makes the difference. With deep expertise in EcoVadis assessments, regulatory frameworks, and ESG best practices, Telesto helps manufacturers accelerate results, avoid missteps, and turn sustainability into a powerful business advantage.

Our people

Ben Vatterott

Partner, San Francisco

Ben Vatterott will provide executive inputs, ESG/sustainability expertise, and overall leadership. Ben brings over 15 years of experience in supporting both local Chicago manufacturers and Fortune 500 companies in creating and scaling ESG/sustainability programs to meet customer needs and ensure regulatory compliance.